During the injection process, there are many reasons for the imbalance of the melting flow. Among them, the flowing imbalance caused by temperature changes is particularly difficult to detect and avoid, which brings great inconvenience to injection molding production. So, is there any good way to solve it? Please contact the Chapman team at any time to get more information and communication.

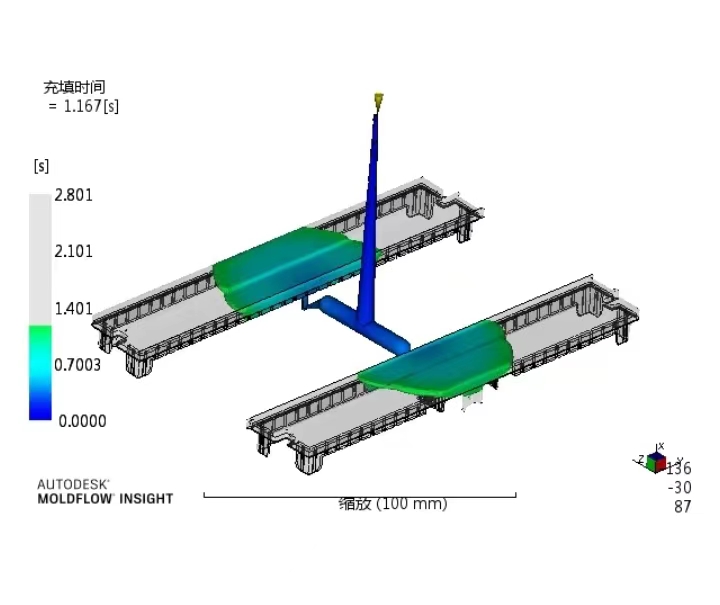

In the process of multi -type cavity formation, it is very difficult to make the melt flow evenly and balanced into each mold cavity. A variety of factors such as different port size or inconsistent shear mode in the flow channel system will cause the molten unbalanced flow. However, few people know that in the thermal flow system, the flow of flow caused by changes in the temperature at the hot pouring mouth is particularly troublesome, and it is not easy to be diagnosed.

The temperature changes in the heat flow channel will not only cause insufficient charging or flying edges during the same injection cycle, but also cause different situations in the different injection cycle. For example, in a 4 -cavity mold, in the first injection cycle, this may occur: the quality made in the second and third cavities is the best quality, and there is insufficient charging mold in the first cavity. The phenomenon of phenomena appears in the fourth cavity.

However, in the next injection cycle, with the continuous changes in the internal charging mode in the mold cavity, the phenomenon of flying edges may occur in the first cavity. The quality of the components is very good. This unbalanced phenomenon is sometimes very serious. It is possible that a cavity is only 50 % filled in this injection cycle, and 100 % is filled within the next injection cycle. This situation often occurs even in the two cavity molds. In actual production applications, whether the required injection pressure is high or low, and the imbalance of the modeling model occurs from time to time.

A small temperature change occurs between one area and another area, and the phenomenon of flowing imbalances during the charging process will cause the melt in a few minutes. Although this very small temperature changes are necessary at the time of production.

Influence of temperature changes

There are many reasons that cause changes in the temperature in the heat flow duct. One reason is that the temperature oscillation occurs at the heat spray caused by the PID controller. With the opening and closing of the heater, the actual temperature of each mold cavity will fluctuate back and forth near the set point, so that the temperature changes between the mold cavity during the injection molding process are different.

For example, the temperature of the first mold cavity is likely to rise, and the temperature of the second mold cavity decreases, which makes the melt flow easier to flow into the first mold cavity. This phenomenon did not improve until the first mold cavity started to cool and the second mold cavity began to heat. At this time, the flow of the melt will gradually reach balance. From the perspective of long -term changes, this temperature change in the cavity occurs every few minutes.

Another reason to cause unbalanced flow is that at the end of each hot mouth at the mouth, a very small coagulation embolism (plugs) will be formed,similar to the cold material (cold slug) formed at the nozzle during each injection process. During the injection process, before the melt flowing into the mold cavity, these embolism must be completely solidified.

However, not all the embolism is completely solidified at the same time. The final solid -to -mold cavity will complete the final charging model, which delays the time of the charging model and reduces the pressure of the model. It may also cause contraction or insufficient charging.

However, because the mold cavity of the final charging is the shortest time before the next injection cycle starts. Therefore, during the injection process, the mold cavity will be completed first, and the pressure in the cavity will increase significantly, resulting in flying edge. From this we can see that the model of the module during each injection process will change differently.

By heating the hot mouth of all mold cavity, the number of embolism can be effectively reduced, thereby ensuring that the flow of the melt is more stable and balanced during each injection process. However, this method is not applicable to all application cases, because there are many reasons for the quality problems of the parts.

Solution

Usually, by changing the setting status of the temperature controller, adjusting the heat runway or the temperature controller, these problems can be solved well. However, for processors, this method does not cure the root causes in more. Installation of pressure sensors in each cavity should be a good solution, which will help improve the accuracy of the process. By analyzing the obtained mold pressure data, the application effect of the selected solution can be effectively evaluated, and the feedback information obtained from the closed -loop system at the same time is provided to the injection machine.

At this time, when the pressure in the cavity reaches the preset value, the injection machine enters the injection stage. By installing the pressure sensor, users can clearly see the different pressure peaks between each mold cavity, and even observe which cavity is first completed and reached the highest pressure peak when each injection.

Generally, before the injection machine enters the second stage (pressure -keeping phase), the first mold cavity that has already begun to charge will continue to maintain the state of charging. If the melt reaches the end of the mold cavity in the first stage of the injection, the pressure in the mold cavity will reach its peak, which will lead to flying edge phenomena.

Reduced the injection speed before the first mold filling, which can effectively prevent peak pressure in the mold cavity. When the charging model reaches 80 % to 90 % , the second -stage low -speed charging mold begins, so as to ensure that the mold cavity will not be charged under too high pressure. The lower charging speed set here is usually 10 % to 20 % of the original charging speed. This low -charging speed should keep the pressure in the mold cavity reaching the pressure required by the component during the pressure preservation phase. This makes the pressure of all mold cavity more uniform.

Generally, people will take it for granted that low -speed injection will extend the injection molding cycle. In fact, the result is exactly the opposite. This is because the unbalanced modeling process requires that there must be sufficient pressure preservation time and cooling time, so as to ensure that the last mold cavity can be fully filled. By using speed instead of pressure to keep pressure, the last mold cavity can quickly complete the charging model, but shorten the injection molding cycle. This method can ensure that the pressure inside the cavity is more consistent at each injection, so that it can obtain better quality consistency without extending the molding cycle.

If you want to know more about multi -cavity molds, please contact us through info@chapmanmaker.com at any time.

Post time: Feb-09-2023